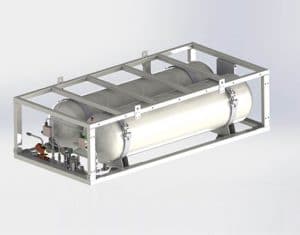

The main equipment of the external hydrogen supply hydrogen refueling station consists of a hydrogen unload column (unloading hydrogen from a long tube trailer), a hydrogen diaphragm compressor, a hydrogen storage cylinder group, a hydrogen refueling machine, etc.

When the hydrogen refueling station adopts the external hydrogen supply mode as the hydrogen source, that is, the hydrogen in the long pipe trailer is compressed into the high-pressure hydrogen storage cylinder group through the high-pressure compressor through the unload column, a long pipe trailer unload position is set at the hydrogen refueling station. When the unloading is completed, the long tube trailer can be directly off the station.

After the hydrogen is stored in the hydrogen storage cylinder group, it is divided into high and medium groups, and formed into a high, medium and low three-stage refueling cylinder group mode together with the lone pipe trailer to realize the graded refueling of the hydrogen fuel cell vehicle. The advantage of this design is that the efficiency is high and the refuelingf time is short, and at the same time it has both safety and reliability. It can ensure that 10 fuel cell buses (8×140L hydrogen storage cylinders) refueling indicators, and the refueling time of a single bus is ≤20min.

According to the process requirements and design control requirements of the hydrogen refueling station, the station control system takes the data acquisition control system and the host computer as the core to form a station monitoring system to realize the monitoring of the entire production process.